Listen for Impact

Michelle Segrest | February 9, 2017

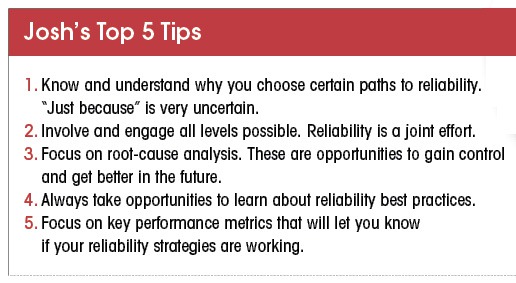

Josh Mattson drives key reliability programs using ultrasound and root-cause analysis.

“When I would see a failure of equipment, the mechanics would come and fix it, but I really wanted to understand what they were doing so I could catch the failures earlier and maybe help with the repairs,” said Mattson, the reliability supervisor for USG Interiors, a subsidiary of USG Corp. “I wanted to be involved at a deeper level.”

He drew inspiration from this quote by author and pastor Andy Stanley: “Leaders who don’t listen will eventually be surrounded by people who have nothing to say.” This philosophy helped him climb the ranks from the production line to a maintenance mechanic, maintenance management, and now reliability supervisor.

“Being a leader and part of reliability, you need to go out and talk to the people running the machines and listen to those who know and understand the equipment and processes,” Mattson said. “That is the most valuable information you can use to help strategize and plan to achieve reliability. Reliability cannot be achieved single handedly. It must be a team effort.”

Mattson has spent his entire 15-year career in Cloquet, MN, with USG Corp., manufacturer of building products and innovative solutions, and currently drives the reliability programs for the interiors division, which manufactures ceiling tile. The company is also widely known for its Sheetrock-brand gypsum wallboard and joint compounds, Durock, and grid products. He oversees maintenance best practices and programs and then identifies and implements new technologies and maintenance strategies.

His team consists of one lube tech and seven planners, all who work daily with about 85 employees consisting of the plant’s team of engineering, mechanical, and electrical groups. With about 370 employees, the facility covers 22 acres.

Mattson said his approach is discovering what programs he can implement that will have the biggest impact on the success of the plant. “I like being able to get into the forefront of all the new reliability best practices, strategies, and technologies,” he explained. “I like researching and implementing new reliability practices and having the opportunity to work with all involved to make them successful.”

Mattson said he builds strength and credibility in his current reliability position from his mechanical background and experience with transitions through previous supervisor and coordinator roles.

“I try to approach life, family, and work with the goal of making a difference,” he continued. “In this role, with the focus on reliability, communication is huge, especially listening. You can’t go out and make something reliable without an understanding. It is crucial to talk to the crafts and production. There are a lot of resources out there. It’s important to search out the subject-matter experts. You can make up a lot of ground in a short time with communication and resourcing.”

Josh Mattson is inspired by a quote from author and pastor Andy Stanley: “Leaders who don’t listen will eventually be surrounded by people who have nothing to say.”

Driving successful programs

This approach has helped Mattson identify key reliability programs for USG. In 2005, the company implemented a reliability-performance model program based on production and maintenance assuming different roles within the program. It emphasized best practices such as preventive maintenance, operator basic care, planning and scheduling, and storeroom management.

“This was a very challenging program to get started because it involved breaking down our comfort and behavioral walls of how our plant previously managed our maintenance needs,” Mattson explained. “As we progressed through the years, it started to become clear how frequently our maintenance departments were reacting to our maintenance needs, and we could easily see that becoming proactive was our biggest opportunity.”

In 2014, USG developed a lubrication-technician position and performed a third-party lubrication audit of the plant, accelerating lubrication best practices and an oil-analysis program.

A big difference was made when Mattson and his team chose to build a program that focused on the use of ultrasonics to detect early failures and assist in lubrication. “As I moved into the role as the reliability supervisor, one of the things that interested me was the P-F (Potential to Failure) curve,” he said. “I had been shown this before, but really hadn’t dissected it. I started to think about reliability in the sense of how to catch failure at the earliest stage so that we can have the ability to analyze and control it.”

“Ultrasound is one of the earliest ways to detect failure coming before vibration, oil analysis, and thermography,” he stated. “It seemed like it wasn’t too complicated with many uses from the instruments. We were already doing a small amount of thermography on some electrical motors and mechanical components, but that’s further down the P-F curve. We resourced UE Systems to help us line up our instruments and get us started with our program. This is where I believe it is very important to align yourself with a group of subject-matter experts who have a multitude of computer-based resources, along with onsite support and training.”

USG first invested in the Grease Caddy, a device that indicates the amount grease needed by a given component by listening and watching the decibel (dB) levels drop. The next instrument was the UP 9000, which monitors trends in mechanical components, such as bearings and gear reducers, by collecting dB data and dumping the information into the Ultratrend DMS software. This allowed Mattson and his team to establish dB baselines and chart the dB data to indicate when to lubricate a given component, catching early signs of failure.

“It was very clear in a hurry that by using ultrasound we were able to support, with data why we chose to lubricate, pull an oil sample, or change out a component,” Mattson said. “It was really crazy how quick the ultrasound rounds turned into our lubrication rounds, and now we only lubricate those components based off ultrasound data, and not time-based or amount-based as we had done previously. We have actually seen dB drops from our first established base line due to the fact that they used to be time- and amount-based lubrication and most likely over lubricated. Switching to ultrasound was a huge leap of faith that was followed up with success.”

“We have found that the more technologies you can bring to your maintenance program the more capabilities you have to support your maintenance decisions,” Mattson said. “You have to weigh which technologies to jump into, and then focus on getting really good at them.”

With every new program, there are obstacles and challenges. “There is always a point where there is a leap of faith,” he explained. “You have to get comfortable with it, then the data will tell you when to lubricate. When you get to this point and go strictly with ultrasound data, you can have a lot of success very quickly. It’s made a huge difference. The mechanics doing the ultrasound rounds began to see why they are doing things, and began to really understand their equipment. Then you get to see how the mean time between failures increases by not changing components as often. And with ultrasound, there is always data to support why we are doing something.”

For Mattson and his team, defining reliability is simple. “For us, reliability means that our equipment is doing what we want it to do, when we want it to do it,” he said. “As engagement on all levels has strengthened here at our plant I was recently involved in another group that defined reliability as, ‘A partnership at every level working toward a common goal of process consistency with zero downtime to meet the customer needs.’ I believe whole heartedly in both of these definitions, with my emphasis being on the common thread that reliability is a group effort and cannot be achieved alone.”

“As I further my path to reliability, I begin to see how vast it is. There is not just one route to get there. You have to understand your processes and equipment to help determine your route to reliability. My advice is to get out there and talk with the production operators and the crafts.”

Along with ultrasound, Mattson and his team have also focused on root-cause analysis as a key tool to improve reliability. Tools such as Cause Mapping and 5Why are used to determine equipment variables and controllables.

“This helps us to create action items to eliminate bad actors and contributing causes, or determine if it’s the actual root cause,” he explained. “We document this for the cause mapping. In many cases we have repeat failures, and it’s usually a lack of documented root cause. We focus on process of elimination through highlighting issues in the cause mapping. As we identify those issues, we dissect and troubleshoot them to determine the root cause. We can then move on progressively until we get equipment running efficiently.”

View Comments