Filters Are More Than Pleated Paper

EP Editorial Staff | October 1, 2021

The money you save buying inexpensive oil filters will be spent, and then some, when excess contaminants shorten asset life.

By Mark Barnes, PhD, CMRP, Des-Case Corp.

Selecting the right oil for a given asset, based on the fundamental physical and chemical properties of a lubricant, is foundational to lubrication success. What is often not addressed with the same degree of engineering rigor is oil-filter selection. Given that 60% to 80% of all lubrication issues are related to inadequate filtration, perhaps it’s time we took a closer look at the filters we use.

Most filter purchases are based on a part number and micron rating. The part number typically does little more than assure that the filter will fit into the appropriate housing or thread onto the filter head with appropriate sealing.

The micron rating is a measure of the size of particles the filter might be expected to capture. However, this is where things are not always as they should be. The micron rating of a filter is nothing more than an extension of the part number code based on one of three measurements of filtration efficiency: nominal, absolute, and beta.

Nominal efficiency: The nominal efficiency of a filter does not have any engineering definition. A nominal filter rating is little more than an estimate by the manufacturer of the filter’s true capture efficiency. When evaluated with more rigorous efficiency testing, such as the multi-pass beta rating test (see below), nominally rated filters often have less than a 50% capture efficiency at the stated micron size, e.g., a 10-micron nominal filter only has a one in two chance of capturing 10-micron particles. Unfortunately, nominally rated filters are often used because they are typically the least expensive.

Absolute efficiency: The term absolute might suggest that a specific filter “absolutely” removes all particles greater than a certain size rating. Since the pore sizes of any oil filter are not uniform throughout the filter, in practice, absolute oil filters rarely if ever perform at 100% capture efficiency for their absolute micron rating. While there are engineering standards that are used to define a filter’s absolute rating, in practice most absolute-rated oil filters have a capture efficiency of 97% to 98% at the stated micron rating.

The beta rating of a filter is measured by comparing the number of particles upstream and downstream of a filter at a given micron size.

Beta efficiency: The beta rating of a filter is a measure of the expected capture efficiency at a given micron size. The test, which is covered under the ISO 16889 standard, uses a multi-pass test stand to empirically determine the capture efficiency of a filter at specific micron sizes (Figure 1). The beta ratio at a certain micron size is simply the ratio of the number of particles upstream of the filter at a given size range versus downstream. In the example in Fig. 1, for every 100, 5-micron particles upstream of the filter, only 10 are measured downstream, giving the filter a beta rating of 10 (100 divided by 10) at 5 microns. From the beta rating, the filter’s capture efficiency can then be calculated as a percentage.

While the filter beta rating is a good indicator of the expected performance, do not interpret the result too literally. The multi-pass test is a lab-based test that is conducted under steady-state conditions. In the real world, pressure surges, changes in flow rates, mechanical vibration, and temperature swings can all affect actual filter performance, based on the structural and mechanical design of the filter. For this reason, several manufacturers have developed variations of the multi-pass test to measure the beta efficiency of filters under variable (stressing) conditions.

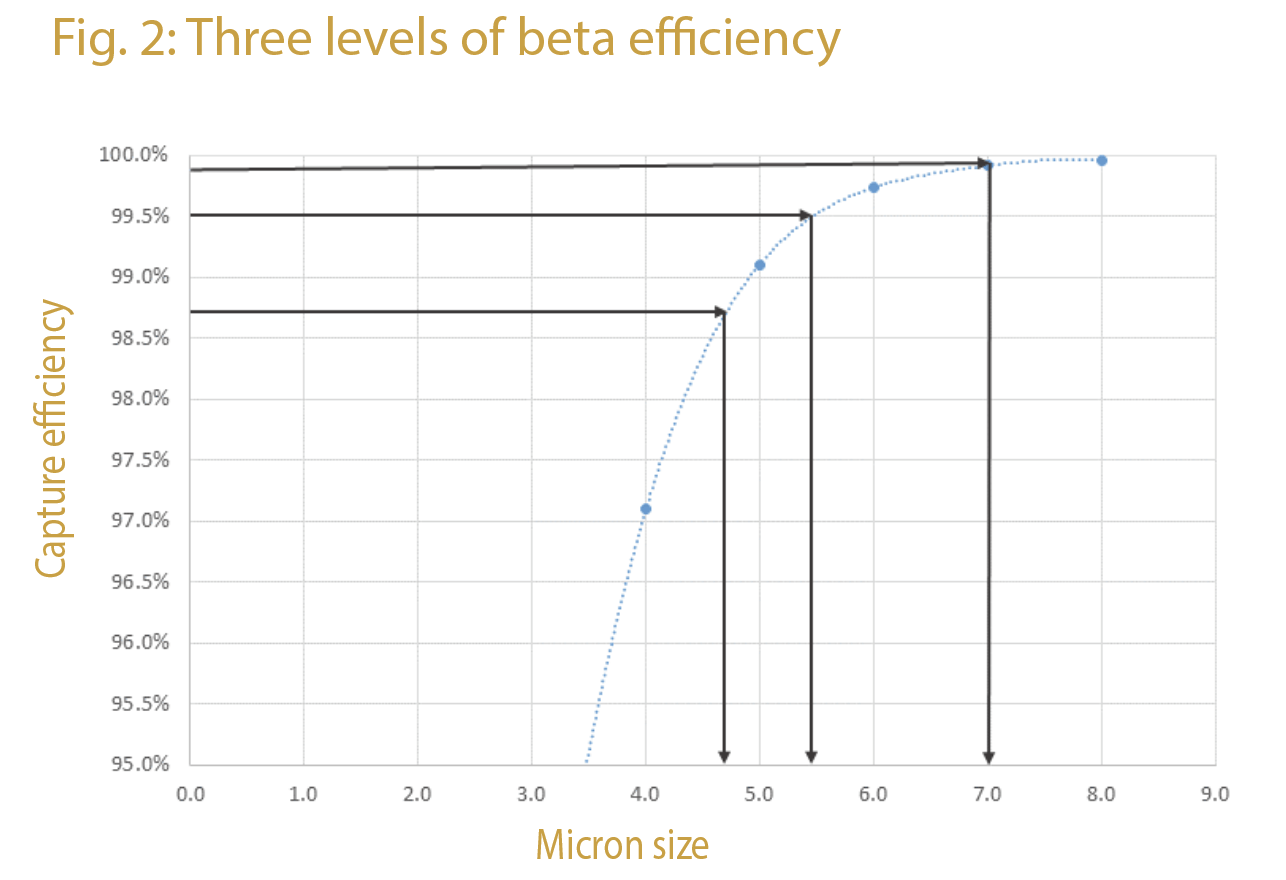

Oil-filter manufacturers report the beta efficiency of an oil filter as the size of particle at which the filter achieves a capture efficiency of 98.7%, 99.5%, and 99.9%.

Whenever possible, filters should be selected based on the appropriate beta rating to achieve the desired (required) ISO 4406 fluid cleanliness. In most cases, manufacturers report the beta efficiency as the size of particle at which the filter achieves a beta rating of 75, 200, and 1,000, equivalent to a capture efficiency of 98.7%, 99.5%, and 99.9%, respectively (Fig. 2).

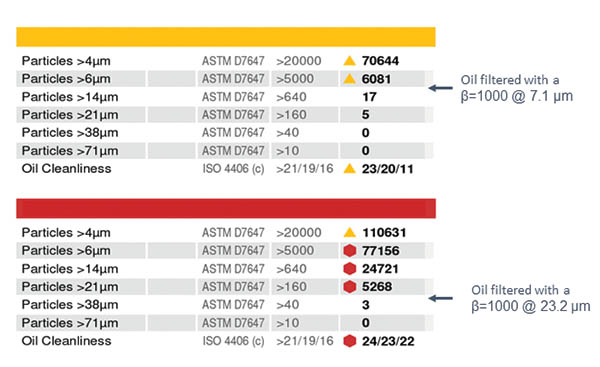

Fig. 3. The impact of beta rating and filter performance for two oil samples is illustrated in the table. Note the sharp cut-off in particles larger and smaller than the filter’s beta 1,000 rating when oil is filtered through a high-quality filter element.

The impact of beta rating and filter performance can be illustrated by the oil samples shown in Fig. 3, which shows the sharp cut-off in particles larger and smaller than the filter’s beta 1,000 rating when oil is filtered through a high-quality filter element.

Filter capacity

In addition to measuring the beta efficiency, the ISO 16889 standard determines the dirt-holding capacity of a filter. This is measured as the number of milligrams of contaminants captured per square centimeter of media before the filter reaches a terminal differential pressure due to particle loading. Dirt-holding capacity for a specific filter is often stated simply as the total amount (weight) of particles a given filter holds, without reference to the total surface area.

This is an important consideration and the crux of why some filters with the same part number and micron rating often perform so differently. Most oil filters, whether they are elements that are inserted into a housing or a simple spin-on filter, are made from pleated filter media. It is the difference in the type of media as well as the design and fabrication of the filter that truly determines how it will perform in each application.

Most high-quality pleated filters use five or seven layers of media to meet the micron rating and provide structural integrity. Pleat depth and quantity determine efficiency and capacity.

Most high-quality pleated filters are made from synthetic microglass with five or seven layers of media (Fig. 4). The outer two layers are usually a wire mesh that provides structural stability. Without this support, filter elements will flex and deform under cyclical loading, pressure spikes, and vibration, causing reduced efficiency and particle sloughing.

The next two layers are a scrim material that provides support to the media and prevents “linting,” which is fine particles shed by the filter media that can increase contamination levels within a system. The final center layer typically comprises either a graded media or a dual, coarse-and-fine layer to provide filtration down to the prescribed micron rating and efficiency.

“Economy filters,” on the other hand, are typically constructed of only three layers and are often manufactured from paper (cellulose) media. This results in an element with lower efficiency and dirt-holding capacity, which in turn results in high particle concentrations in hydraulic and lubricating oil systems. Cellulose can also channel or swell in the presence of water, rendering the filter ineffective at particle removal. For this reason, cellulose-based pleated elements are not typically recommended for critical applications.

Aside from the number of layers, pleating depth and the number of pleats also play a significant role in efficiency and capacity. Shorter and/or fewer pleats for a given filter circumference will offer significantly less surface area, meaning that, all else being equal, the filter will not hold as much dirt before it goes into bypass. In fact, some economy filters can have 30% to 40% less surface area. This results in an equivalent reduction in dirt-holding capacity.

When it comes to lubrication and asset reliability, fluid cleanliness is paramount. Make sure that you understand how clean your system needs to be for optimum reliability, think carefully about how well the filter is constructed, and consider how it will work to protect critical assets. Filters are much more than simply a product code and micron rating. They are precision components that should be selected based on sound engineering principles and contamination-control best practices. EP

Mark Barnes, CMRP, is Senior Vice President at Des-Case Corp., Goodlettsville, TN (descase.com). He has 21 years of experience in lubrication management, oil analysis, and contamination control.

View Comments